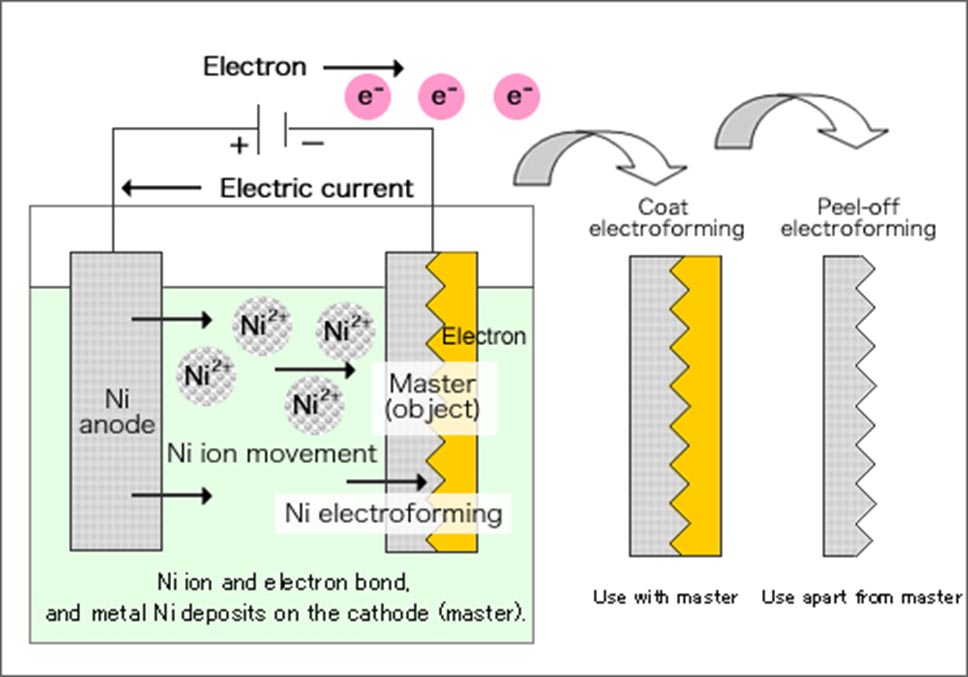

1) Electroforming stencil

ʻO ke kumu hana o ka stencil electroformed: hana ʻia ka template electroformed ma ka paʻi ʻana i ka mea photoresist ma ka papa kumu metala conductive, a laila ma o ka masking mold a me ka ultraviolet exposure, a laila ua electroformed ke template thin i ka wai electroforming.ʻO kaʻoiaʻiʻo, ua like ka electroforming me ka electroplating, koe wale nō ka hiki ke wehe ʻia ka pepa nickel ma hope o ka electroforming mai ka papa lalo e hana i kahi stencil.

Loaʻa i ka stencil Electroforming nā hiʻohiʻona: ʻaʻohe koʻikoʻi i loko o ka pā kila, ʻoluʻolu loa ka paia o ka puka, hiki i ka stencil ke ʻano mānoanoa (i loko o 0.2mm, hoʻomalu ʻia e ka manawa electroforming), ʻo ka hemahema ke kiʻekiʻe ke kumukūʻai.ʻO ke kiʻi ma lalo nei ka hoʻohālikelike ʻana o ka mīkini kila laser a me ka pā kila kila electroformed.ʻOi aku ka maikaʻi o ka hopena demoulding ma hope o ka paʻi ʻana i ka paia puka maʻemaʻe o ka mīkini kila electroformed, i hiki i ka lakene wehe ke haʻahaʻa e like me 0.5.

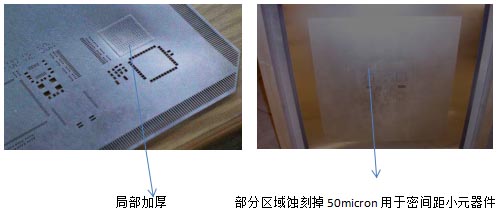

2) ʻO ka penikala alapiʻi

Hiki ke mānoanoa a i ʻole ka mānoanoa o ke kila kila.Hoʻohana ʻia ka ʻāpana mānoanoa e paʻi i nā pad solder e koi ana i ka nui o ka solder paste, a ʻike ʻia ka ʻāpana mānoanoa e ka electroforming, a ʻoi aku ke kumukūʻai.Hoʻokō ʻia ka ʻili ʻana ma ke kalai kemika.Hoʻohana ʻia ka ʻāpana lahilahi e paʻi i nā pads o nā mea liʻiliʻi, kahi e ʻoi aku ka maikaʻi o ka hopena demolding.Hoʻohana ʻia nā mea hoʻohana i ʻoi aku ka maʻalahi o ke kumukūʻai e hoʻohana i ka etching kemika, ʻoi aku ka maʻalahi.

3) Nano Ultra Coating

ʻO ka uhi ʻana a i ʻole ka hoʻopaʻa ʻana i kahi papa o ka nano-coating ma ka ʻili o ka mesh kila, ʻo ka nano-coating e hoʻokuʻu i ka paia o ka lua i ka paʻi solder, no laila ʻoi aku ka maikaʻi o ka hopena demolding, a ʻoi aku ka paʻa o ka paʻa o ka paʻi solder paste.Ma kēiaʻano, uaʻoi aku ka paʻa o ka maikaʻi o ka paʻiʻana, a hiki ke hoʻemiʻia ka helu o ka hoʻomaʻemaʻe a me ka holoiʻana i ka mesh kila.I kēia manawa, hoʻohana wale ka hapa nui o nā kaʻina hana i kahi papa o ka nano-coating, a nāwaliwali ka hopena ma hope o kekahi helu o ka paʻi ʻana.Aia nā nano-coatings i hoʻopaʻa ponoʻia ma luna o ke kila mesh, iʻoi aku ka maikaʻi o ka hopena a me ka lōʻihi, aʻo kaʻoi aku o ke kumukūʻai.

3. Papalua solder paste kaʻina hana.

1) Paʻi/Paʻi

Hoʻohana ʻia nā mīkini paʻi ʻelua e paʻi a hana i ka paʻi solder.Hoʻohana ka mea mua i ka stencil maʻamau e paʻi i nā pads o nā mea liʻiliʻi me ka pitch maikaʻi, a ʻo ka mea ʻelua e hoʻohana i ka stencil 3D a i ʻole step stencil e paʻi i nā pad o nā mea nui.

Pono kēia ʻano paʻi paʻi ʻelua, a he kiʻekiʻe hoʻi ke kumukūʻai o ka stencil.Inā hoʻohana ʻia kahi stencil 3D, pono ʻia kahi ʻōpala huila, kahi e hoʻonui ai i ke kumukūʻai a haʻahaʻa hoʻi ka hana hana.

2) Paʻi/puʻu ipu

ʻO ka mea paʻi paʻi solder mua e paʻi i nā pā liʻiliʻi liʻiliʻi, a ʻo ka mea paʻi inkjet ʻelua e paʻi i nā pad mea nui.Ma kēia ala, ʻoi aku ka maikaʻi o ka hopena solder paste molding, akā kiʻekiʻe ke kumu kūʻai a haʻahaʻa ka maikaʻi (e pili ana i ka helu o nā pads nui).

Hiki i nā mea hoʻohana ke koho i ka hoʻohana ʻana i nā hoʻonā i luna e like me ko lākou kūlana ponoʻī.Ma ke kumu o ke kumu kūʻai a me ka hana pono, e ho'ēmi i ka mānoanoa o ka stencil, me ka hoʻohana 'ana i haʻahaʻa-koi aperture lākiō stencils, a me step stencils oi pono koho;hiki i nā mea hoʻohana me nā huahana haʻahaʻa, nā koi kūlana kiʻekiʻe, a me nā mea hoʻohana koʻikoʻi koʻikoʻi ke koho i ka papahana paʻi/jet printing.

Ka manawa hoʻouna: ʻAukake-07-2020